PLA insulation foams offer good thermal insulation, acoustic insulation and fire resistance properties and can be used in various applications including the construction sector. They are also known for their biodegradability reducing their environmental impact compared to non-biodegradable foams.

In addition to the aforementioned properties PLA foams also offer moisture regulation preventing mold in building and thus improving the indoor air quality for the occupants.

Overall, PLA insulation foams represent a promising option for environmentally conscious consumers and industries seeking sustainable alternatives to conventional insulation materials.

Product development

The aim of this task is the synthesis of a bio-based polyol derived from lactic acid, that is scalable and stable, designed to meet the requirements for application in the formulation of flexible polyurethane foams for the construction sector. This way, the content of bio-based material in the PUR formulation can be considerably increased. For this purpose, different routes of synthesis, raw materials and experimental conditions have been investigated to achieve a polyol with optimal molecular weight, viscosity and hydroxyl number similar to fossil-based commercial ones.

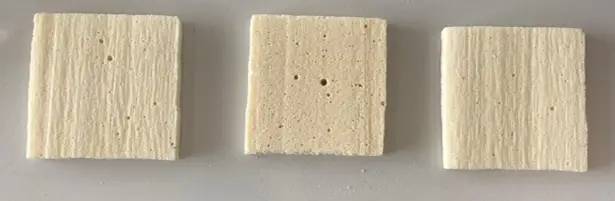

In this way, several polyols have been synthesised and characterised (IR, NMR, GPC and hydroxyl number assay) to confirm that the different synthesis steps were properly carried out and to determine that the polyols had appropriate hydroxyl number and viscosity functionality. After several experiments, results showed that several polyols obtained fit with the technical requirements for their use in PUR flexible foams formulation, being a bio-based viable solution instead of using commercial petrol-based ones. Finally, one of these formulations was selected and scaled up, controlling and modifying the key parameters to achieve a sprayable polyol.

On the other hand, a flame-retardant additive for PLA foams, derived from DOPO (9,10-dihydro-9-oxa-10- phosphaphenanthrene-10-oxide), was developed through an innovative and sustainable process designed and optimized using AIMPLAS’s know-how and protected under patent WO2023/09452. This process eliminates the use of halogenated intermediates found in conventional methods, prioritizing environmental sustainability and process efficiency. Using this approach, the synthesis has been successfully scaled from 1 g to 800 g, with concrete plans to further scale production to 1-2 kg per batch, aiming for future industrialization and applications in the plastics sector.

Product safety

- For safe use of the product, the following precautions are recommended:

- Avoid skin and eye contact. Wear chemicalresistant gloves and protective goggles during application.

- Do not inhale vapours or aerosols. Work in wellventilated areas; for intensive application, use a respirator with an organic vapour filter (A2 type).

- If accidental contact occurs, wash skin with water and soap; if it reaches the eyes, rinse for 10 minutes and seek medical advice.

- Products must be stored at a temperature between 5 and 35°C. Prevent water from entering the storage place.

- PLA foams fully react during foaming, forming an inert solid material. Once cured, no specific hazards are expected.